- Germer Technologies Pvt. Ltd.

- info@germer.co.in

GERMER TECHNOLOGIES PVT. LTD. can regenerate used

lead-acid & nickel-cadmium batteries, regaining lost run

time and increasing the life span of the batteries.

Batteries lose capacity through sulphation and now we

have imported New Electronic Technology from Europe

which is totally unique and achieves results not seen

previously in the Battery World.

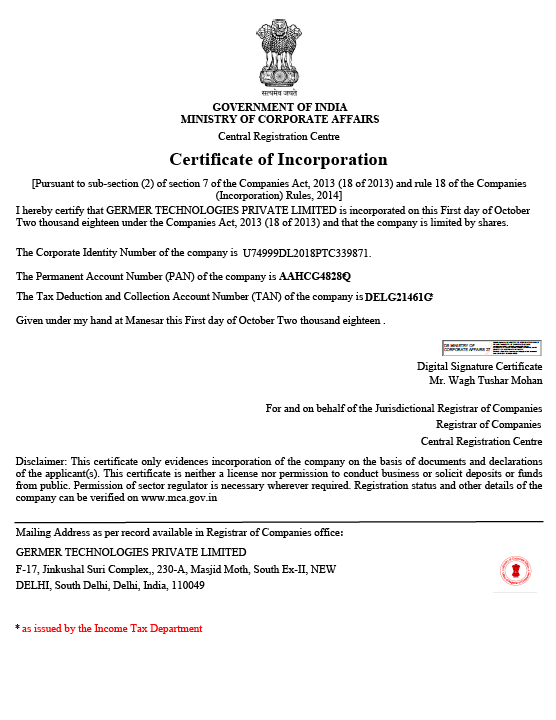

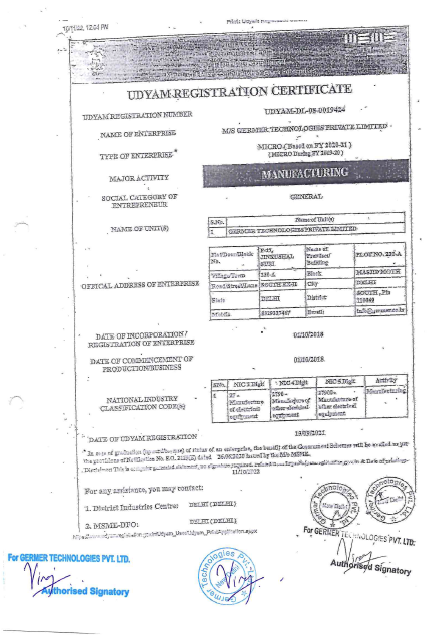

GERMER TECHNOLOGIES PVT. LTD. is an innovative and

climate smart Indian Company at Noida, Uttar Pradesh.

Our unique technology for cost effective re-use of

lead-acid batteries is being used. GERMER TECHNOLOGIES

PVT. LTD. was established in 2018 as GERMER and has

become a true clean tech company. By our forceful

expansion we are today a forerunner for ground-breaking

total service concepts in the battery business where

regeneration and re-use of batteries by means of GERMER

Service significantly reducing the cost for batteries at

improved performance before the battery eventually must

be recycled.

GERMER cooperates with recognized and

successful environmentally friendly battery producers.

Together with our global cooperation partners we offer

complete full-service agreements, including the supply

of batteries, as well as the provision of GERMER Service

and preventative battery maintenance.

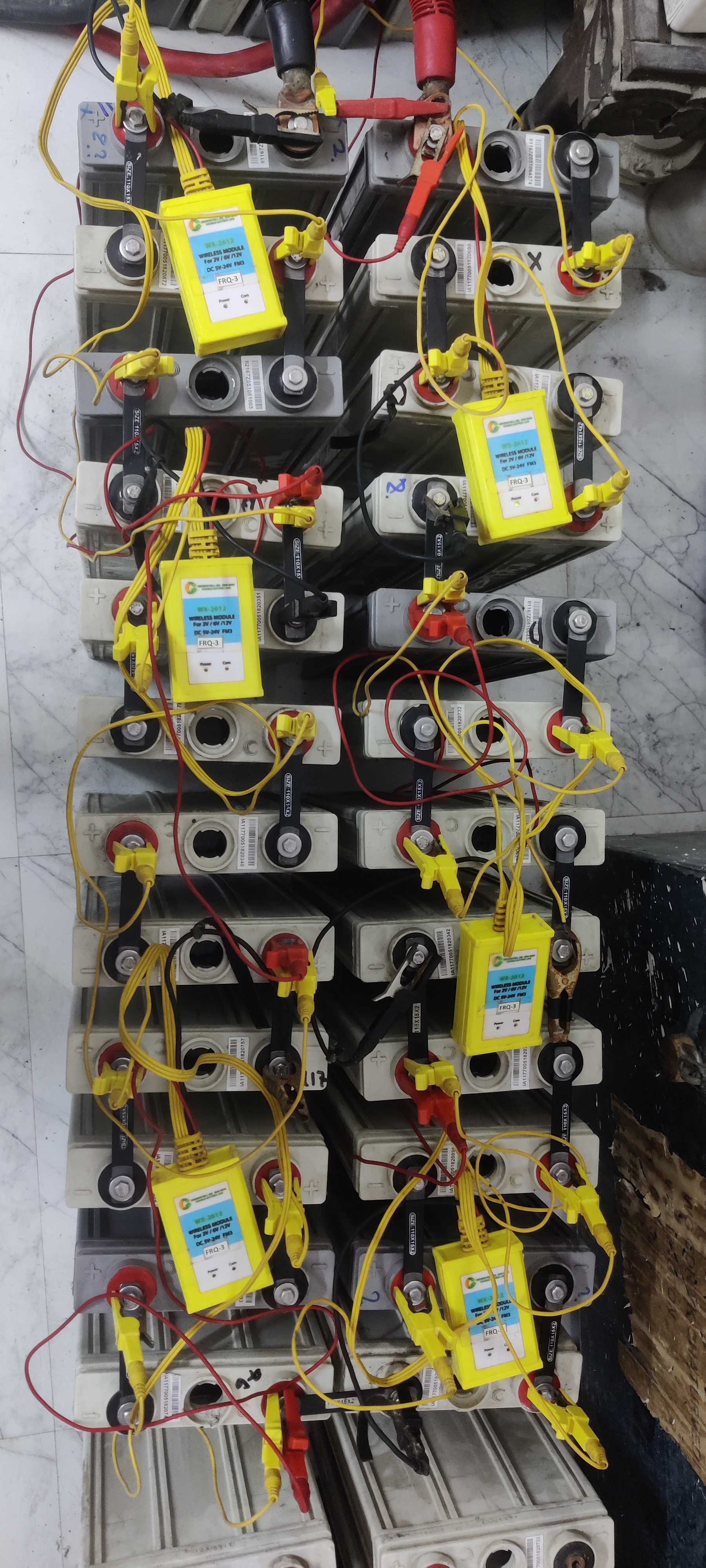

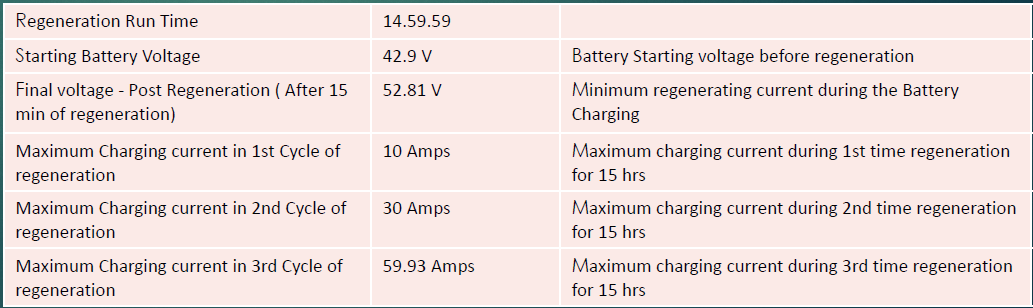

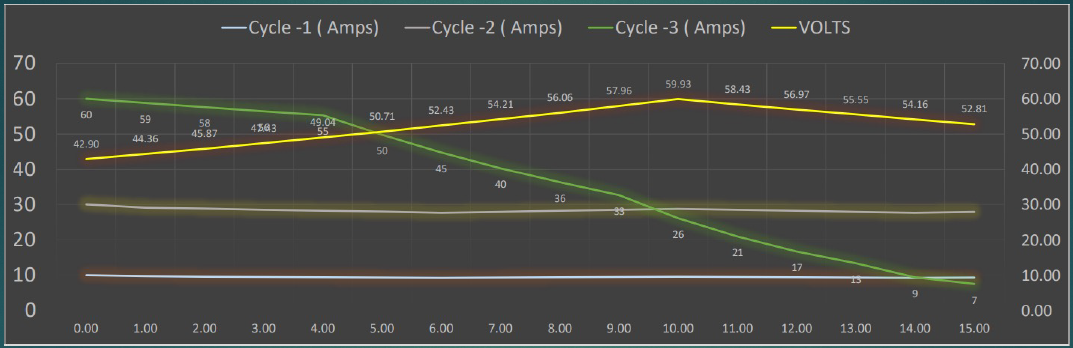

48 Volt is one of most popular voltage level for batteries applications.

The 48V battery groups are most common back up energy option for telecommunication DC power system. For important telecom devices, the performance of battery groups is crucial. Because when a power outage happens, battery groups are the only power supply for keeping DC power system operating uninterruptedly. Obviously, the periodical discharge test is essential for checking the ability of batteries in use.

RNC48100 chargers use the latest power electronics technology and intelligent micro processing technology, combined with computer data processing software to intelligently control the battery charging process. Easy to operate, effectively reduce the work intensity of maintenance personnel, improve maintenance test efficiency, reduce the enterprise cost, and provide a comprehensive scientific detection means for the battery group.

Battery preventive maintenance is very important in reducing the risk of any downtime and unplanned capital investment. Germer Battery has the capability of performing preventive maintenance on all aspects and types of lead-acid & nickel-cadmium batteries. These solutions include diagnostics testing of all battery chemistries and parameters. Germer Battery offers a comprehensive battery preventive maintenance incorporated with regeneration and monitoring system. With the latest & innovative green technology and advanced software, Punaha Battery is the 1st in the nation with such capabilities.

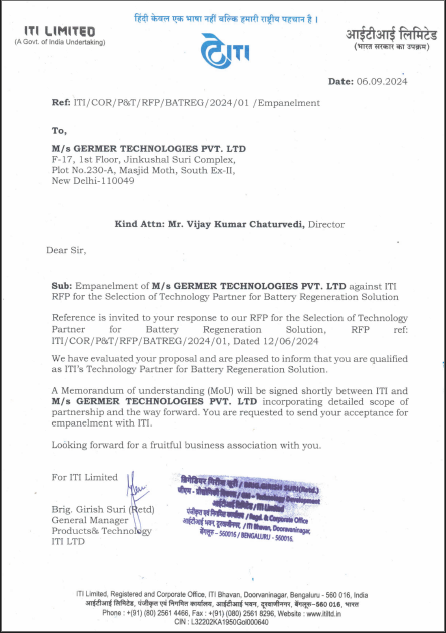

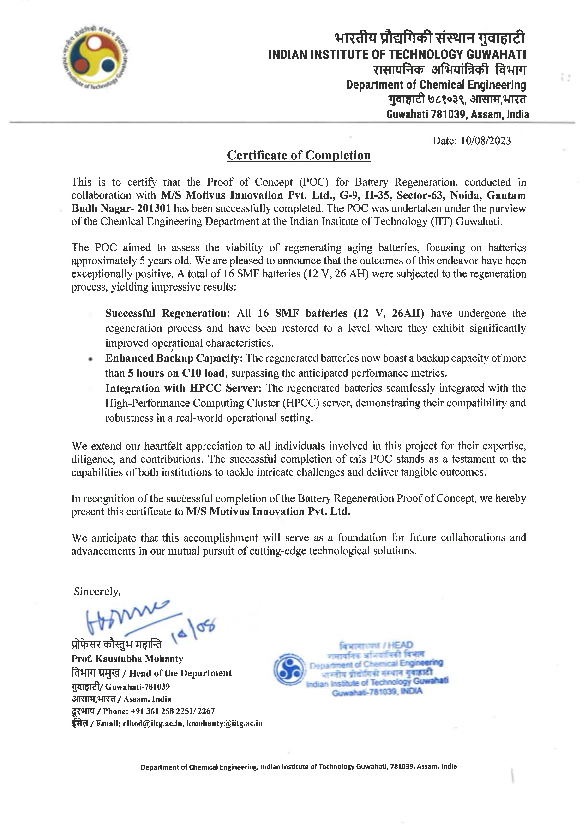

To offer reliable one stop centre for battery related services and service partner to government agency to reduce environmental waste. Germer Battery shall be the brand related to battery life extension. Germer Battery shall prepare solutions for the next evolution of battery regeneration in collaboration with Indian Telephone Industries (ITI), Delhi Metro Rail Corporation(DMRC), Indian Air Force (IAF) & Noida Metro Rail Corporation Ltd. (NMRC), India. It is inteded to expand the service as a franchise model across the Indian sub-continent as the sole distributor of the technology in India.

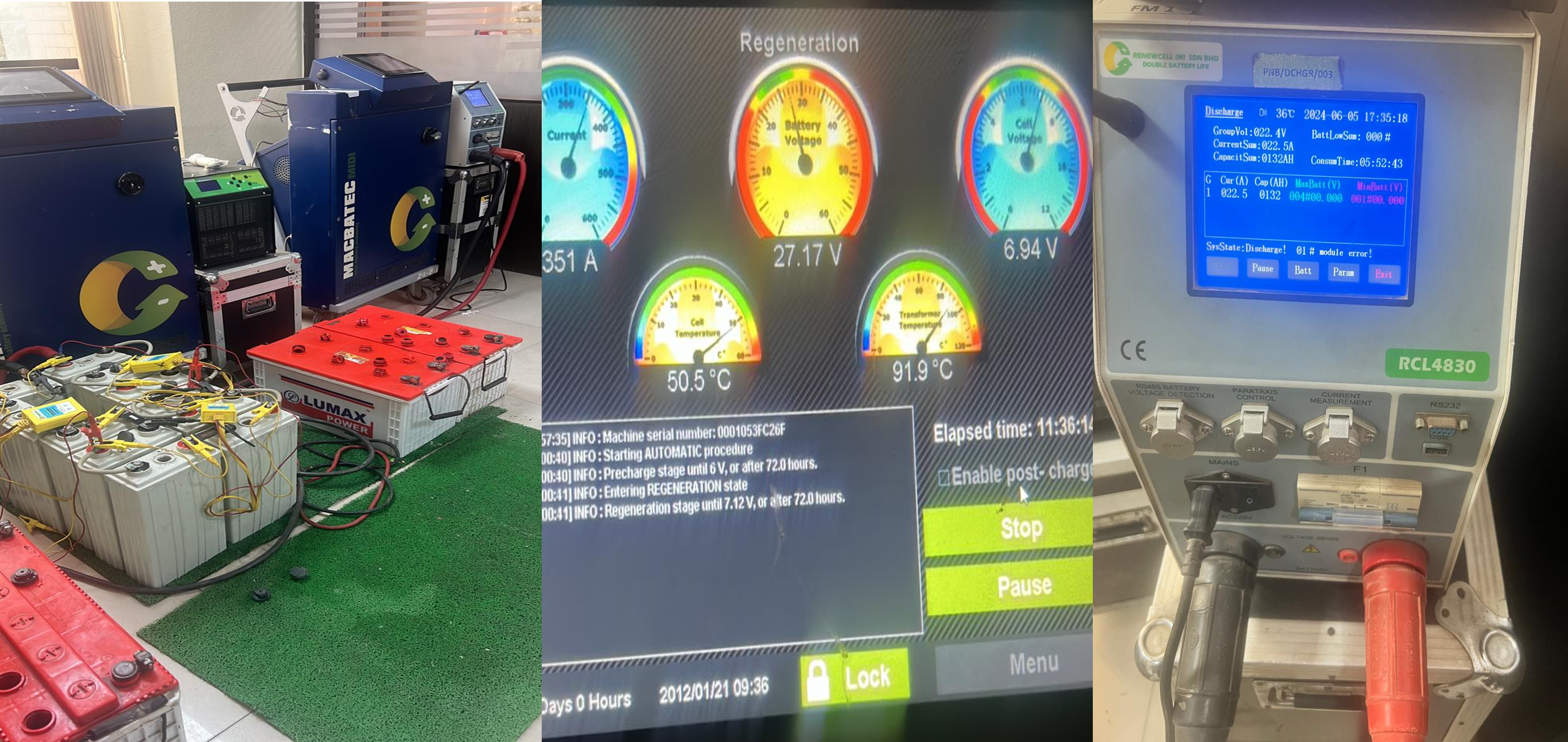

Battery Regeneration Technology offfered by

GERMER works on the hard sulphation

by cracking the crystals and turning them into

amorphous forms. Reaching this level of efficiency is

crucial, which is achieved by superior technology of

regenerator machine & the associated software.

The level of efficiency, automation and long-term

support ensure the best battery restoration and

regeneration results. Battery recondition can be done

regularly through a maintenance service or once through

a full service.

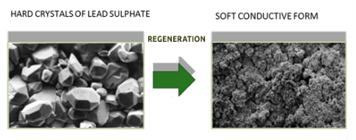

Battery Regenerators used by Germer restore lost battery

capacity through carefully controlled current pulses.

The pulses break down the lead sulphate crystals that

suffocate the battery and return them to their amorphous

form (a process known as desulphation). The amorphous or

spongy form is the active material used by regular and

HF chargers to increase the specific gravity of the

electrolyte and recharge the battery.

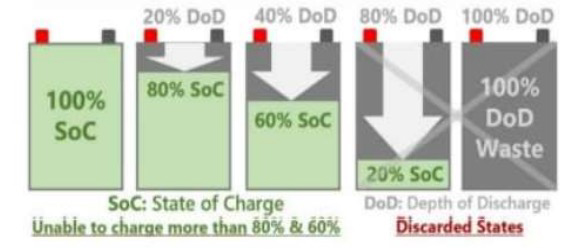

Crystals or hard sulphation is the inert material that

causes damage to batteries. This is because they serve

as insulation (offering a strong resistance to the flow

of electric current) and also because they are

physically larger. (they pressure the electrodes

mechanically)

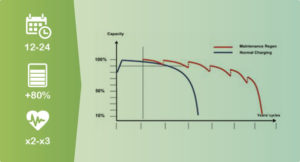

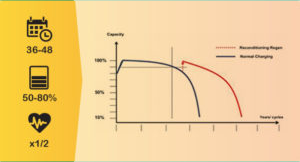

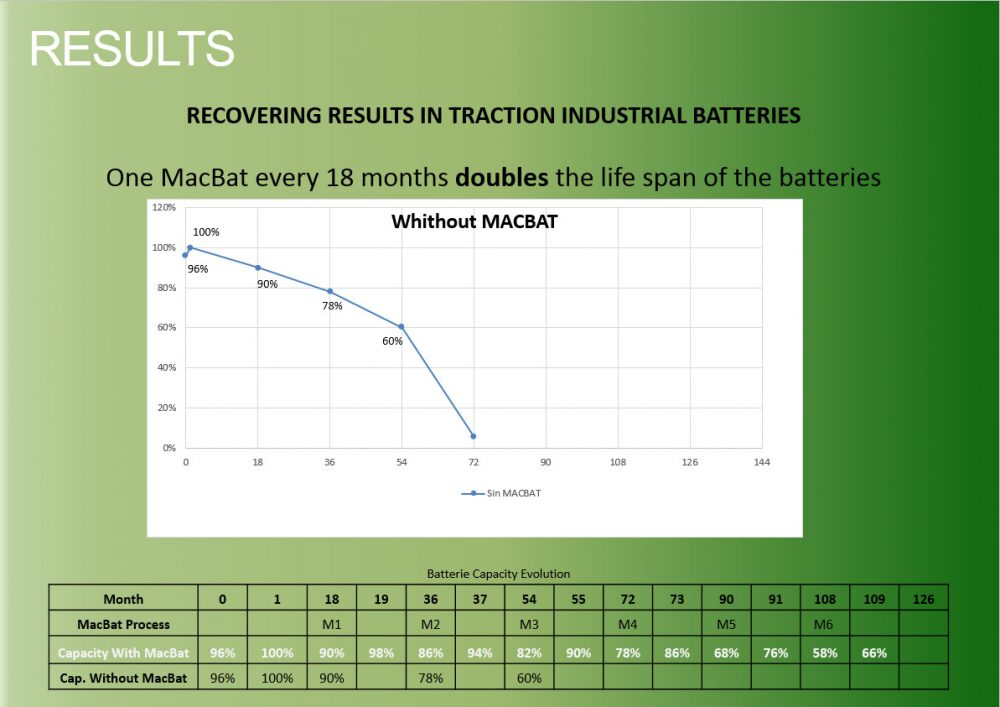

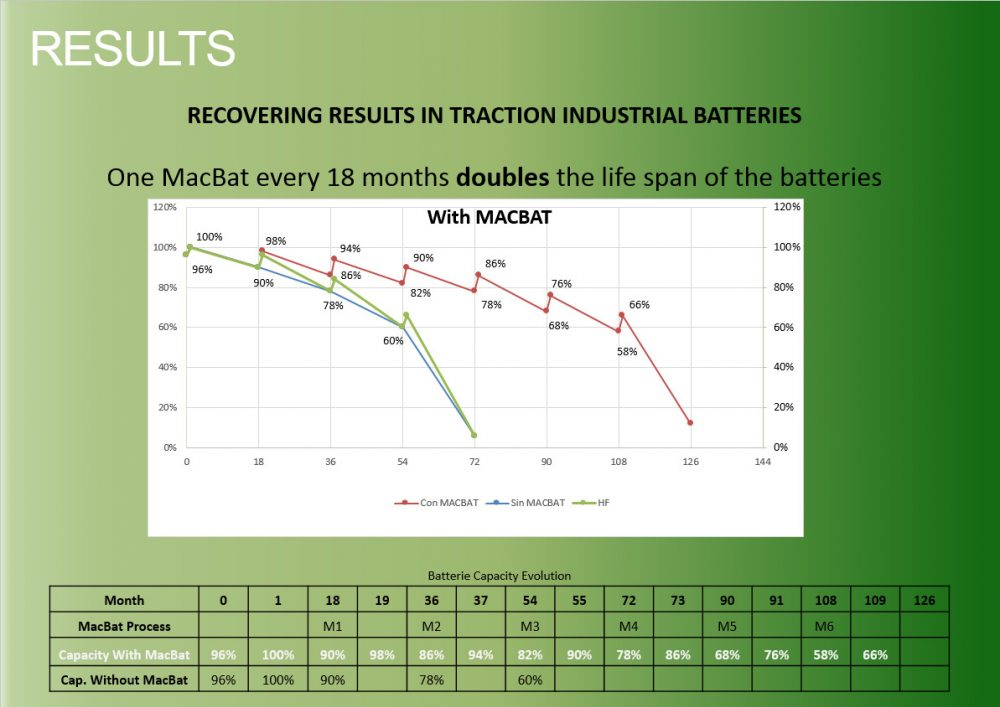

This service is done regularly every 12-24 months while sulphation is still low, and the battery is at 80% or more of its capacity with no electromechanical damages. Through thisregular maintenance, our battery regenerator will recover the battery level to nearly the maximum provided by the manufacturer and double or even triple the life span. (depending on the battery type and application).

This service is for used batteries that have lost a significant portion of their capacity. Our battery regenerator will recover up to 50% of lost capacity, depending on the type of damage and how the battery recovery process is done. Be sure to follow up with maintenance services to keep the battery capacity at a high and uniform level.

Germer Battery regeneration application can be used in many industries. Some of them include ForksLift, UPS Battery Banks, Marine Industry, Defence Applications, Automotive, Telecom and Solar Industries, etc. The technology used is environmentally friendly & results in significant saving of costs and as well as carbon emmisions.